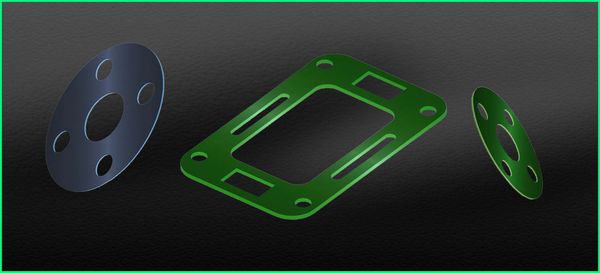

Non-Metallic Gaskets

A Non-Metallic Gasket (Soft Gasket) uses zero metal in it composition.

Soft gaskets are made from large variety of elastomers, compressed non-asbestos, PTFE, flexible graphite and high temperature sheet products.

Compressed Non-Asbestos

Compressed non-asbestos gasket materials combine non-asbestos fibers such as fiberglass and aramid fibers with rubber to enhance the temperature and pressure performance of the gasket.

- NBR/Aramid

- Neoprene/Aramid

- SBR/Aramid

- EPDM/Aramid

- NBR/ Carbon

Flexible Graphite Gaskets

All flexible graphite gaskets have excellent resistance to corrosive chemicals, high temperatures and high pressures. They also exhibit excellent thermal conductivity and an ability to securely seal.

- Flexible Graphite (Homogeneous)

- Flexible Graphite (316SS foil insert)

- Flexible Graphite (316SS tanged insert)

- Flexible Graphite (Mylar Film Insert)

Rubber

A rubber gasket is a sealing product used to fill the space between two or more mating surfaces generally to prevent leakage of air, chemicals, gases, or liquids from or into the joined objects while under compression.

- Neoprene (CR)

- Nitrile / Buna-N (NBR)

- Red Rubber (SBR)

- Pure Gum Rubber

- Ethylene Propylene (EPR, EPDM) Butyl

- Polyurethane

- Fluorocarbon (FKM)

- Silicone

- Fluorosilicone

PTFE

Virgin PTFE gaskets are made from 100% pure material which is used in most general applications. It is extremely soft and formable and is often used for chemical resistant seals and gaskets.

Glassed Filled PTFE gaskets are made from PTFE which integrates glass fibers in order to improve the mechanical strenght performance of the gasket.

590 Fawn Filled with glass microspheres

590 is filled with silica and meets a wide range of applications. It is suitable for general service, strong acids and moderate caustic solutions. It meets FDA conformance for service within food and pharmaceutical applications.

580 Off-White Filled with barium sulfate

580 is filled with barium sulfate and is suitable for strong caustic fluids. Can be used in a wide range of applications due to its vast resistance to most chemical products. It is compatible with strong acids along with strong caustics.

570 Blue Filled with silica

570 is filled with glass microspheres and is suitable for aggressive chemical applications. 570 is the preferred material for fragile flanges, glass lined equipment or other applications that require higher compressibility.

Other

CORK

PLANT FIBER

PLASTIC

POLYURETHANE

Expanded PTFE

One Team expanded PTFE joint sealant is a soft, compressible gasket material made of 100% pure, expanded PTFE. It is a form-in-place gasket that conforms to almost any sealing surface.

It is also easy to install and remove, making it a highly versatile and cost-effective solution for many demanding sealing applications.

- Sizes Available 1/8" to 1"

- Temp Range -450 deg F to 525 deg F

- pH Range 0-14

- PSI 3,000

Valve Packing

One Team Valve Stem Packing is an all-Purpose, self-forming packing material made of virgin PTFE. It is a round, expanded product, resulting in a fibrillated, High Tensile Strength material that deforms when compressed to fill all surface irregularities.

PTFE Stem Packing is self-lubricating, eliminating stem wear, and is unaffected by most common chemicals.

It has an operating temperature range of -450ºF to +500ºF, contains no contaminants, and is highly resistant to chemical attack.

Available Diameter: 1/16" to 1/2"

Tape

One Team offers numerous grades of tapes in varying densities, thicknesses and colors, which can be used in general purpose, demanding, or critical services. Whether you are trying to seal water, steam, pure oxygen, or anything in between, we’ve got a thread sealant tape for you.

- White threaded metal and plastic pipe connections.

- Purple Maxx™ heavy-duty tape.

- Grey Nickel-Filled PTFE for stainless steel pipe connections.

- Yellow gas Line

- Green oxygen service

- Pink water, steam

- PTFE Pro-Grade Thread Sealant Compound (aka pipe dope)

Gaskets

Expanded PTFE Sheet is a high-performance sheet gasket material made of multi-directionally expanded virgin PTFE. It is a soft, form-in-place gasket material that conforms to almost any sealing surface.

It is capable of withstanding a wide range of pressure, temperature and chemical environments. Due to its highly fibrillated microstructure, it has excellent creep resistance compared with other PTFE products.

Thickness 1/32” to 1/4"

Multi-directional

Gasket Tape is a soft flange gasket material made from Multi-Directionally Expanded PTFE. The multi-directional expansion results in a material with superior Creep Resistance compared with other PTFE gasket materials. It is made of 100% PTFE for excellent chemical resistance.

Thickness 1/8” and 1/4", and widths of 1/2" to 2”

Our Gasket Tape is ideal for:

- Large flanges

- Glass-lined and plastic flanges

- Flanges with limited available space

- Flanges where compressed thickness is important

Semi-Metallic Gaskets

Spiral wound gaskets are the most commonly used gasket for high temperature and pressure service combinations.

They can be manufactured in various metals depending on the operating temperature, media, and compatibility.

The principle construction requires the use of alternate plies of “chevron” V shaped metal wire with soft non-metallic filler to offer optimum performance.

This design generates excellent recovery properties to maintain an effective seal.

These are made in accordance to ASME B16.20 latest edition, ASME B16.5, and ASME B16.47 flanges.

Style S

Style S is a spiral wound gasket that is fabricated by utilizing the metal wire along with soft non-metallic filler.

This style does not incorporate the use of an inner and outer ring. Suitable for tongue and groove, male and female, or grooved to flat face flange assemblies

Style GS

Style GS are comprised of the metal wire with designated filler incorporating the use of a solid metal outer ring.

The outer guide ring promotes the proper centering of the gasket in a standard flange, offers radial support for the outer portion of spiral wound, and acts as compression gauge to prevent over compression of the spiral wound.

These are typically supplied in mild carbon steel, and can be changed to another metal dependent upon service conditions.

Style GSI

Style GSI are same as our Style GS with the only difference being an additional inner ring.

Just like the outer ring, the inner ring serves multiple functions as well.

This allows for radial support for the inner portion of the spiral wound, help prevent inward buckling, and helps to provide uniform gasket stress.

Style GSI-LL

Style GSI-LL are fabricated to provide an effective seal at moderate or lower seating stresses.

This design requires lighter bolt loads to seal and still have the recovery of a Style GSI.

The GSI-LL is typically used in 150# and 300# class flanges where there is concern regarding insufficient bolt loads.

We utilize the latest technology to electronically control and calibrate densities to meet almost any requirement.

Style GSI-HF

Style GSI-HF gaskets are designed for highly corrosive applications, such as Hydrofluoric Acid (HF).

This style offers the advantage of having double sealing design which occupies all the space from the bore of the pipe to the outer diameter of raised face flanges.

The spiral wound can be fabricated to the customers specifications. Typically, we will use either Kammprofile Carbon Steel (Teflon Coated) or Monel Inner ring faced with Graphite or PTFE.

This Kammprofile Inner ring is affixed to the “special” spiral wound. The GSI-HF gaskets are designed to inhibit corrosion resistance, especially in HF service.

Style GSI-HTG

Style GSI-HTG are GSI spiral wound design for higher temperature applications.

The winding construction is made up of a Mica and APX2 Graphite configuration.

The combination of the two materials provides oxidization and corrosion resistance (Mica) along with the excellent “sealability” of APX2 Graphite.

The Mica filler along with the metal serve as internal or external oxidation barriers between for the APX2 Graphite.

Corrugated & Double Jacket Gaskets

Corrugated Metal Gaskets

CMS and CMH range of gaskets are fabricated using the latest technology to enable excellent recovery during thermal cycles.

The core is usually made of Corrugated Metal from a wide range of alloys with soft sealing material facing on both sides.

All CMS and CMH styles are designed to promote exceptional performance for applications involving extreme thermal cycling and flange joint relaxation.

These are primarily used in 150# and 300# class flanged assemblies. The corrugated core along with soft facing sealing materials can be custom engineered for each application.

- FG-PTFE is good solution for aggressive chemicals and requires fire safe properties.

- HTG is good thermal contraction and expansion in the flange assembly, used at higher temperatures and in oxidizing environments.

- FG graphite facings for standard piping Class 150 & 300lb and on small to large heat exchangers.

- EPTFE can offer a great sealing solution in aggressive media applications.

Double Jacketed Metal Gaskets

Style DJH (Double Jacketed Heat Exchangers)

Style DJH are custom made to order double jacketed construction gaskets mainly for heat exchangers, boilers, and other vessels.

These are made to order with usually drawing or all dimensional and construction data specified. Our Technical Group can assist in choosing the proper alloys and filler materials if unsure.

Style DJHC – (DJ Heat Exchanger Corrugated)

Style DJHC are fabricated in the exact same manner as our Style DJH, with the exception of the outer metallic shell being corrugated.

This style can also be faced with soft sealing filler if requested to meet lower bolt load or other applicational requirements.

Kammprofile Gaskets

Kammprofile gaskets are manufactured with the best practices using the latest manufacturing technology.

These are the preferred gasket of choice to maintain a tight seal for heat exchangers, pressure vessels, and other equipment that are subjected to excessive thermal cycling.

Kammprofile gaskets are constructed with concentrically serrated solid metal core faced on both sides with the correct flexible sealing material depending upon the application.

These are commonly specified to improve performance where lower gasket seating stresses are required for an effective seal.

This design limits the movement of the sealing material within the serrations while the solid metal core provides blowout resistance and firmness for ease of installation.

Type 1

Style KP-1 are constructed with solid serrated core only for use in confined spaces, male and female, tongue and groove, or recessed flange compositions. These are most commonly found in heat exchanger flanges as upgrade from double jacketed or solid metal where lower bolt load is required.

Type 2

Style KP-2 are fabricated similar to KP-1, except with an integral outer guide ring to assist in proper alignment on flange facing. This gasket is recommended for raised face or flat face mating flanges.

Type 3

Style KP-3 are very similar to our KP-2 with minor difference of utilizing a loose-fitting guide ring for alignment. This design is used in place of KP-2 where thermal expansion is encountered.

HTG

KP-1-2 & 3 are all available with our HTG sealing layers, the inner section of the sealing element is mica, the middle section is APX2 Graphite, the outer section again is mica. The mica inner and outer sealing rings act as an oxidation shield for the APX2.

Enabling this design to operate up to a maximum temperature of 1500 Deg F (815 Deg C).

Metallic Gaskets

Metal gaskets are designed to resist extreme temperatures, pressures and chemical exposure.

Offered in regular and custom configurations, these rugged metal gaskets are made of a wide range of materials to accommodate all types of process applications.

Octagonal - Oval - Rubber Coasted

(OCT) Octagonal cross section has a higher sealing efficiency than oval.

Oval gaskets are applied at wide range of industry today.

(RC) Ring Joint Gaskets coated with rubber are used in hydrostatic testing of equipment.

BX

BX-Type are suitable for high pressure applications.

Pressures up to 15,000 psi

Type BX Type A & B

Made to API 17D for Subsea Wellhead and Tree Equipment.

Vented cross-drilled holes to prevent pressure lock

RX

RX-type ring-joint gaskets that are used for high pressure applications.

Type RX Type A & B

Made to API 17D for Subsea Wellhead and Tree Equipment.

Vented cross-drilled holes to prevent pressure lock

OTHER

Lens type gasket is a line contact seal for use in high pressure piping systems and in pressure vessel heads.

Bridgeman gasket is a pressure activated gasket for use on pressure vessel heads and valve bonnets.

For pressures of 1500 psi and above.

Delta gasket is a pressure actuated gasket used primarily on pressure vessels and valve bonnets

High pressures in excess of 5000 psi.

Copyright © 2021 ONE TEAM PRODUCTS - All Rights Reserved.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.