SEPCO is a leading manufacturer of standard & custom engineered mechanical seals.

The key to gaining long seal life always lies in selecting the right mechanical seal design for your service, and the right materials of construction for process compatibility.

A cartridge mechanical seal is a completely enclosed seal system with pre-assembled components, making installation much easier, and decreases installation errors.

Provides long lasting and reliable service, cartridge seals will save you money.

- Improved reliability

- Improved performance

- Assembly is "pre-set"

- Pressure tested

- Decreased installation errors

- No installed length calculations

- Seal faces are protected from damage during installation.

- Installation much easier

SEPCO has been providing solutions for almost 100 years.

Cartridge Seals

Balanced Single Spring Seal

The SEPCO BSS is capable of handling higher operating pressures than conventional unbalanced single spring designs.

- Large coil springs are resistant to clogging

- End play to 1/8″

- Balanced, single spring seal

Externally Set Double Seal

he SEPCO ESD is a back to back multiple seal designed for application where positive lubrication is required from an external flush without dilution of product.

- Economic

- Excellent in extremely corrosive and abrasive fluids.

- All metal parts are isolated

Cartridge Grease Seal

The SEPCO CGS is a single, cartridge mounted mechanical seal that can be used to replace double seals without using a water flush. The unique feature of the CGS Seal is a grease barrier cavity to prevent product leakage to the atmosphere without elaborate environmental controls.

- Easy installation

- High PV factors

- Eliminates misalignment / reduces wear

- Non-clogging

Split Seal

The SEPCO VSR is a single, external cartridge mounted rotary seal design for installations where shaft deflection exceeds the limits allowed by off-the-shelf cartridge seals.

- Completely self contained unit

- Pre-assembled and pre-set

- Cooler operation and extended reliability

- Fully Repairable

Unitized Multiple Cartridge Seal

The SEPCO UMC is a stationary design multiple spring double seal used where leakage of hazardous or costly products cannot be tolerated and where positive lubrication without product dilution is required.

The SEPCO UMC is a stationary design used where: Leakage of hazardous or costly products cannot be tolerated. Positive lubrication without product dilution is required.

- Multiple spring double seal

- Positive lubrication without product dilution is required

Reciprocal Balance Duplex Seal

The SEPCO RBD is a stationary design multiple spring double seal used where leakage of hazardous or costly products cannot be tolerated and where positive lubrication without product dilution is required.

Low Temperature Cartridge Metal Bellows Seal

The SEPCO Low Temperature Cartridge is a single non-pusher, rotating welded metal cartridge design. The edge welded cartridge design has the flexibility to fit in ANSI+ and DIN standards Seals are manufactured to disperse the stresses on the welds.

- Rugged design

- Extremes of high temperatures

- High precision lapping finish offers optimal sealing performance.

High Temperature Cartridge Metal Bellows Seal

The SEPCO HTC is a cartridge metal bellows seal using grafoil secondary seals to handle elevated temperatures without any adverse effects.

Hot Oil Seal

The SEPCO HOS is a balanced single spring rotary seal capable of handling conditions much higher than conventional single spring designs.

- Fits Narrow Stuffing Boxes

- Slotted glands offers more versatility with bolting patterns

- Easy installation

- No Installation Measurements

- No Shaft Fretting Wear

Double Tandem Pumper

The SEPCO DTP is a multiple, cartridge-mounted mechanical seal. Ideal for closed-loop convection cooling systems and being reciprocally balanced, it offers a higher operating pressure.

- Ability to function in either tandem or double mode

- Capable of handling surge conditions.

- Rugged and dependable

Vertical Single Rotary Seal

The SEPCO VSR is a single, external cartridge mounted rotary seal design for installations where shaft deflection exceeds the limits allowed by off-the-shelf cartridge seals.

- Completely self contained unit that is pre-assembled and pre-set

- Cooler operation and extended reliability

- Fully Repairable

Single Rotary Cartridge Seal

The SEPCO SRC is a single internal cartridge mounted rotary seal designed for general service applications.

- Will not fret or wear equipment

- Runs cooler at higher operating pressure

- Prevents clogging from suspended solids

- Fits standard ANSI stuffing boxes and oversized seal cavities

Component Seals

Component mechanical seals are the simplest design of mechanical seals and are commonly used as a better alternative to dynamical packing systems.

Component, mechanical seals consist of a separate rotating member and stationary seat that mount in a gland or housing.

Since they are not preset, installation and maintenance are generally more difficult requiring experienced technicians to properly install and adjust them.

- Reduced expenses on initial seal purchase

- Reduced spares costs as the individual components can be stocked vs. the entire seal

- Superior adaptability to very small pumps

Conical O-Ring mounted seal designs are manufactured to be efficient and versatile.

Diaphragm mechanical seals are robust solutions ideal for pump equipment manufacturers

ONE TEAM supply a range of balanced and unbalanced multiple spring seals that are ideal for corrosive and demanding applications.

Parallel O-Ring mounted seals are designed to eliminate the risk of misalignment due to pressure on the shaft-end.

Elastomeric bellows seals are designed so that all rotary components are contained with no loose parts that could potentially get damaged during fitting.

Wave springs are compact bidirectional seals originally designed for short working length and hygienic requirements.

Metal bellows mechanical seals work in extreme conditions:

- High pressures

- Extremely elevated temperatures

- Chemically corrosive products

- High frequency

- Intensity vibration

Accessories

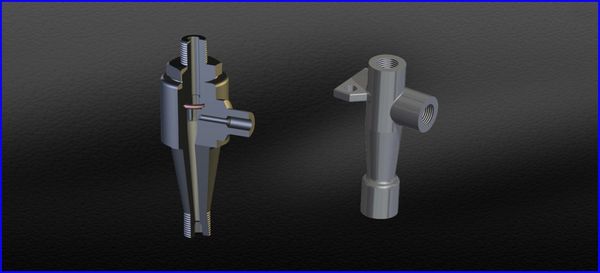

Abrasive separators provide a simple yet extremely effective method of keeping dirt and other abrasives from the sealing faces.

A method that can increase seal or pacing life many times over to greatly reduce replacement and maintenance costs.

Available Materials:

- Nylon

- Stainless Steel

This high-performance, synthetic barrier fluid is the workhorse of seal lubricants. It meets most barrier and buffer fluid needs within chemical, petrochemical, pipeline, ethanol and other biofuel, and refinery plants.

STL-5 Barrier Fluid is ideal for mechanical seal systems in ethanol production. Available in a 5-gallon container.

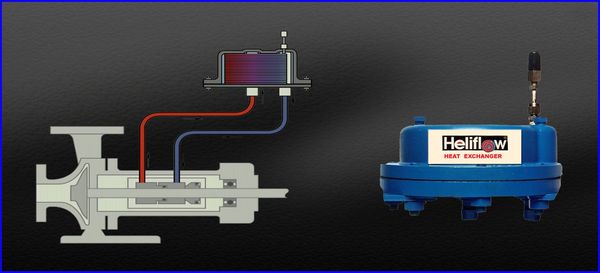

The SEPCO Heliflow (Heat Exchangers) is a unique type of shell and tube heat exchanger.

The tubes in the Heliflow are arranged in parallel, starting with an inlet manifold on one end, and terminating at an outlet manifold on the opposite end.

The tube bundle is wound into a helical pattern.. This coiled construction creates a spiral flow path for the fluid inside the coil.

The SEPCO model SSF sealing liquid monitor is designed for applications where uninterrupted seal water flow is required.

Adequate seal water flow for cooling and lubrication result in water savings, energy savings, reduced maintenance, and extended life of seals.

The SSF is compatible with all seal types. The sturdy modular construction and many accessories make it very flexible.

SEPCO’s Water Management System utilizes the pressure available from the plant water line to pressurize the barrier fluid inside the vessel.

This provides a pressurized barrier fluid that maintains a stable fluid film across the seal faces which most mechanical seals require.

The check valve protects the plant water line from process contamination and also maintains the maximum pressure from the plant water line.

The Flow Indicator visually makes the user aware that an inboard seal leak has occurred.

Copyright © 2021 ONE TEAM PRODUCTS - All Rights Reserved.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.